A forklift is a small industrial vehicle that has a power-operated fork platform attached to the front, which can be raised or lowered and moved by inserting the fork under the load. Forklifts serve the needs of a variety of industries, including warehouses and other large storage facilities. Forklifts are powered by electric batteries or internal combustion engines. Some forklifts allow the operator to drive and operate the machine while seated, while others require the operator to operate while standing. It is widely used across industries to transport materials and goods.

Let’s discuss in detail the key components of a forklift, the forklift mechanism and its applications.

Key components of forklifts you need to know

A forklift is made up of various components needed to handle the task efficiently. From the frame, power source to counterweight, they are all necessary conditions for the forklift to work efficiently.

1. Frame

The truck frame is an important component that forms the basis of the machine. All of the forklift's key components, including wheels, counterweights and mast, are attached to the truck frame.

2. Balance device

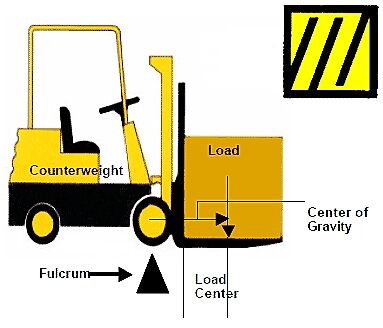

The counterbalance is a cast iron weight attached to the back of the forklift. The purpose of the balancing device is to balance the lifted load without tipping over.

On electric forklifts, the balancing device is fixed to the lead-acid battery.

3. Power supply

The power source of a forklift consists of an internal combustion engine. The engine can run on liquefied petroleum gas, compressed natural gas, diesel and natural gas as fuel. Electric forklifts are powered by fuel cells or lead-acid batteries.

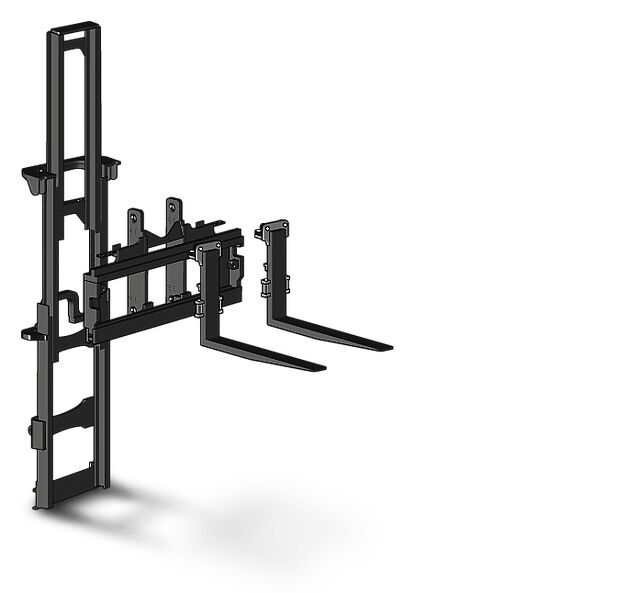

4. Fork rack

The fork frame is fixed on the mast guide rail for easy movement up and down.

5. Mast

The mast is a vertical section that pushes the load up and down. The mast assembly consists of interlocking rails that provide horizontal control. Like fork racks, masts may be equipped with rollers.

How does a forklift work?

A forklift is powered by two intertwined mechanisms:

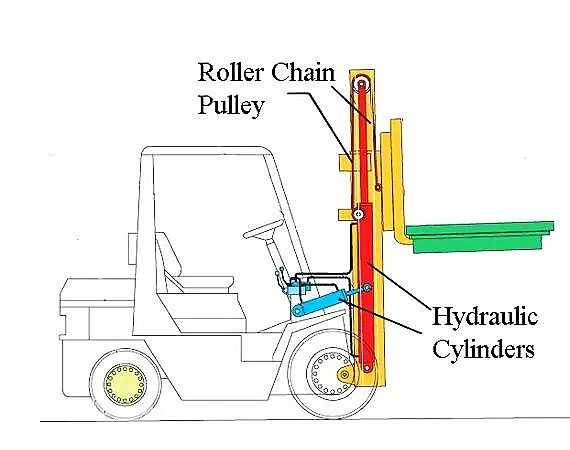

1.Pair of hydraulic cylinder

2. Pair of roller sprockets

3. Controller

4. Lifting mechanism: hydraulic cylinder

The lift handle is connected to an electric air pump on the bottom of the forklift. —Once the handle is depressed, it triggers the air pump, which draws outside air through the filter and forces it into a pipe that leads directly to the hydraulic cylinder. The hydraulic cylinder consists of a hollow tube with a closed end and a piston with flexible lubrication at one end. Air is trapped through the bottom of the cylinder so that gas can enter without leaking out.

The volume of gas in the cylinder increases the pressure in the cylinder. The pressure exerted on the piston head area creates an upward force. This force moves the piston upward, increasing the volume of the gas and reducing the pressure. It creates a physical balance at the height of the forklift and creates equivalent forces from the gas and the forklift load.

1. Increase the load

The operator pushes the handle forward, signaling the forklift to pump excess air into the cylinder.

2. Reduce the load

The operator pulls the handle back, which indicates that a special valve vents gas from the cylinder.

3. Use a forklift to reduce your lifting process: Lifting mechanism - roller sprocket

Hydraulic pistons are attached to two main vertical structures called "masts." The fork used to carry the cargo is connected to the body of the forklift by a pair of roller sprockets, the fulcrum of which forms the gear at the top of the mast.

So when the hydraulic piston pushes the mast upward, the gears on the mast are pressed against the roller chain. This happens because one side of the chain is attached to the forklift's immovable frame, and the only way the mast can move upward is when the gear rotates clockwise and pulls the fork overhead. The significance of this mechanism is that it keeps the fork out of reach of the cylinder. If it doesn't work with roller sprockets, then the forklift will need a taller cylinder to lift the load to the same height.

Forklifts have two sets of control devices: one for steering and the other for lifting.

1. Steering control

Steering controls work like a golf cart, with an accelerator pedal, steering wheel, brakes, reverse and forward gears. The forklift uses rear-wheel steering. When you turn the steering wheel, the rear wheels on the rear axle begin to turn back and forth. This is intentionally designed to allow the operator greater rotation and precision when handling cargo.

2. Lift control

The lift control consists of two levers: one for lifting the fork up and down, and the other for tilting the load forward and backward. The lift control works on the same principle as the lift mechanism discussed above. The tilt mechanism is different. Two additional hydraulic cylinders are attached to the base of the mast.

Once the "tilt handle" moves forward, air automatically fills the cabin. The increase in pressure is enough to push the head of the piston, moving the mast away from the body of the vehicle.

Once the "tilt handle" is moved back, the air gently leaves the cylinder and is pumped to other parts of the cylinder connected to the mast. When the piston pushes forward, the mast is pushed back against the vehicle.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

UZ

UZ