Understanding the forklift stability triangle is critical to workplace safety. When workers understand their vehicle's capacity limits and the general principles of the stability triangle, they can operate safely on the job and reduce the risk of dangerous accidents. This article details the details of the forklift stability triangle and how to ensure that the forklift remains stable during material handling and does not create a safety hazard for you and your staff.

What is the forklift stability triangle?

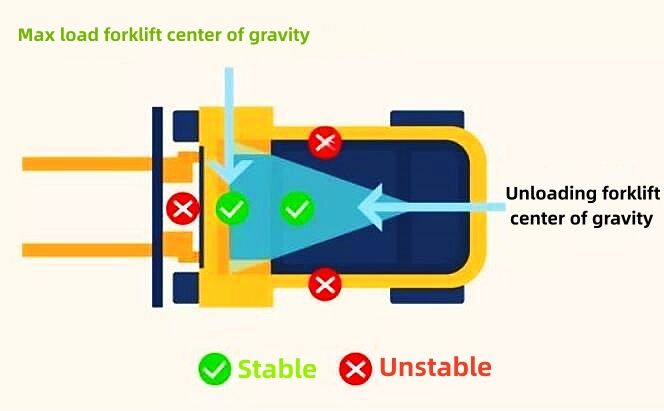

The forklift stability triangle is an invisible triangle formed by the pivot point on the rear axle and the two front wheels connected to the front axle. As long as the center of gravity of the load is within this stability triangle, the forklift will not roll over. If you compromise on the stability triangle, for example, if your forklift carries too much weight in the front, it may cause the forklift's center of gravity to move too far forward, causing it to tip dangerously.

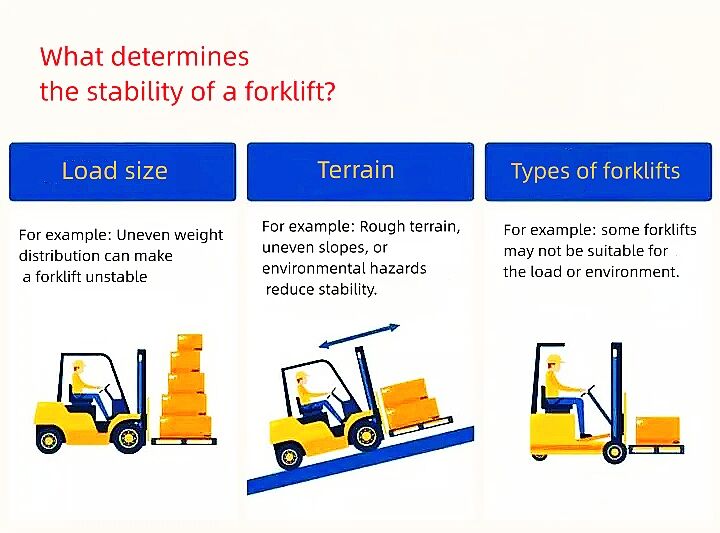

1. Load size

When it comes to load, you should consider the size and distribution of the load. Every forklift has a specific defined load capacity that you should adhere to, which will describe these two factors. For example, a forklift can carry 4,000 pounds at a 24-inch load center, but only 2,666 pounds at a 36-inch load center. Never exceed the capacity described on the forklift data plate or nameplate or you risk being tipped over.

2. Topography of the operation

The terrain a forklift operates on can also affect its stability, as slippery and uneven surfaces have the potential to tip the vehicle over even without exceeding the load limit. Forklift operators should avoid driving over oil, water or other spills due to the risk of slipping. They should also avoid steep inclines and drops, or generally uneven surfaces. Forklift operators should also be aware of obstacles, holes and speed bumps, which can also cause the vehicle's wheels to rise.

3. Type of forklift used

There are many different types of forklifts you can use, each with its own stability profile. If you want to buy a forklift, carefully check the specifications of the forklift to determine which one is suitable for your job.

Although you can find several types of forklifts, each one is suitable for a specific job. For example, you wouldn't want to use a forklift to complete smaller tasks and do heavy warehouse lifting. Or, if you need to move longer objects like pipes and lumber, you'll want a forklift ideal for the job, such as a side loader.

Tips for improving forklift stability

Proper safety training is the key to forklift stability, which can improve the stability of the forklift and reduce the risk of tipping. Remember these are general tips: Check your forklift safety manual for additional safety instructions.

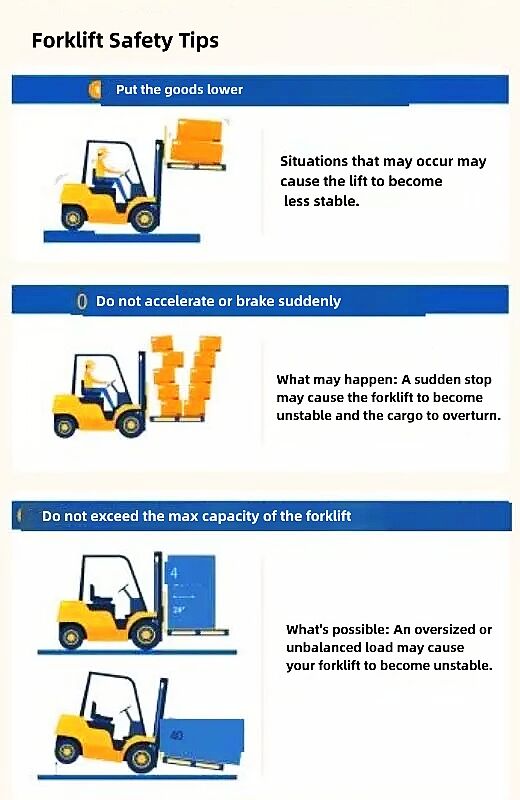

1.Keep cargo low to the ground

The higher the load, the more unstable it will be, so try to keep the load as low as possible from the ground. Ideally, you want the load to be only 4 to 6 inches off the ground. OSHA recommends tilting the mast back and placing the heavier parts as close to the cabin as possible to prevent your center of gravity from moving too far forward. Keep the mast tilted back when traveling for greater stability.

2.Do not accelerate or brake suddenly

Sudden movements will affect the stability of the forklift, so do not accelerate or brake suddenly. Move slowly, gradually, and carefully. Maintain control of the forklift at all times and adjust speed as needed.

3.Do not change direction suddenly

This will cause the center of gravity of the combination to shift rapidly, causing the vehicle to overturn. Never turn on a ramp or any surface grade.

4.Do not exceed the carrying capacity

As mentioned above, the load capacity has a great impact on the stability of the forklift, so never exceed the load capacity described on the vehicle data plate or nameplate. Exceeding the payload capacity can quickly cause the operator to either roll over or lose control of the steering. Make sure all crane operators on site are familiar with the vehicle's load capacity.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

HY

HY

AZ

AZ

KA

KA

UZ

UZ